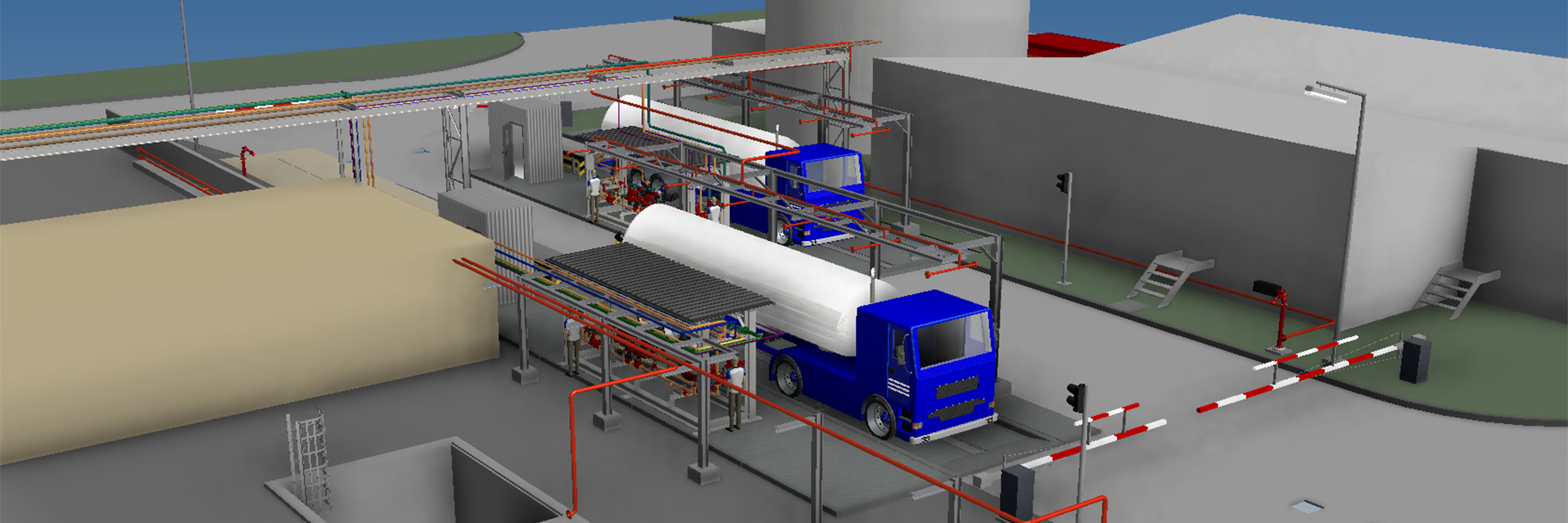

Our range of services

Secure and highly available!

The complexity of the planning of the systems includes all the trades required for their creation and their safe and highly available operation.

Your advantage:

Determination of bases, preliminary planning, design planning, approval planning, complete delivery, turnkey construction, documentation, supervision, commissioning and training.

– ALL FROM ONE HAND –

Our service profile essentially consists of:

This primarily involves an extended basic needs assessment for planning a project including in particular:

- Basic investigation

- Preplanning

- Design engineering

Basic investigation

- Determining the prerequisites for solving the tank farm planning

- Clarifying the task definition for support structure planning and proving structural safety

- On-site inspections and clarification of planning data

- Establishing the scope of services and the necessary preliminary tasks such as subsoil investigations and surveying services

- Summarization of results

- Selecting and inspecting similar objects

Preplanning

- Project and planning preparation, analysis of the basics

- Coordination of objectives through spatial planning, regional planning, building planning as well as local and regional specialist planning

- Examining possible solutions in terms of structural and constructive design, practicality, economic efficiency and taking into account environmental compatibility

- Obtaining and evaluating official plans

- Development of the planning concept including alternative possible solutions in graphic representation and evaluation

- Clarification and explanation of essential subject-specific contex

- Preliminary negotiations with local authorities and other specialists involved in the planning

- Participation in explaining the planning concept to economic and political committees

- Revision of the planning concept according to customer requirements and authorities

- Development of the final cost estimate based on the final preliminary planning

- Compilation of the preliminary planning results

- Preparation of topographical and hydrological documents

- Calculation of special components

Design engineering

- Elaboration of the planning concept, taking into account all subject-specific requirements using other specialists involved in the planning, up to the complete draft. Preparation of explanatory reports

- Specialist calculations of the entire tank farm design without structural calculations

- Graphical representation of the overall design

- Creation of the construction schedule and cost plan

- Negotiations with authorities and others involved in the planning regarding the ability to obtain approval

- Obtaining extracts from the land register, cadastre and other official documents

- Summary of all design documents

This is about the further development of the basic engineering for planning a project essentially consisting of:

- Approval planning

- Execution planning

Approval planning

- Preparation of documents for the necessary public law procedures

- Preparation of the building directory using the contributions of other specialists involved in the planning

- Structural calculations

- Submission of these documents by the buyer

- Land acquisition plan and land acquisition register

- Negotiations with authorities and completing and adapting planning documents

- Descriptions and calculations using the contributions of other specialists involved in the planning

- Participation in the plan approval process, including participation in discussion meetings and participation in the drafting of statements on concerns and suggestions from the approving authority

- Accompanying the approval process up to the approval decision

Execution planning

- Incorporation of the result from the approval planning, taking into account all subject-specific requirements and using the contributions of other specialists involved in the planning until the solution is ready for implementation

- Graphical and mathematical representation of the object with all the individual information necessary for execution, including detailed drawings at the required scales

- Developing the basics for the other specialists involved in the planning and integrating their contributions until the solution is ready for implementation

- Updating the execution planning during the execution of the object

- Preparation of process and usage plans

Procurement, an important tool for a plant manufacturer. Full responsibility and guarantee for EPC (Engineering, Procurement and Construction/turn key) or EP (Engineering and Procurement) by the Dipl.-Ing. SCHERZER GmbH. High-quality equipment “Made in Europe” for plant construction. The components supplied by SCHERZER are usually in use for decades and can be operated for more than 25 years with regular maintenance and repair.

If the EPC project (turnkey construction) has been agreed, assembly is one of our tasks.

If the EP project (Engineering and Procurement) has been agreed, it is one of the customer's tasks. If it is contractually regulated, the Dipl.-Ing. specialists are available. Scherzer GmBH is available to monitor and ensure proper and professional assembly on site.

- Supervision of the local construction monitoring and coordination of those technically involved in property monitoring, in particular checking for compliance and approval of third-party plans

- Setting up and monitoring the schedule

- Putting the executing company in default

- Acceptance of services and deliveries with the participation of the local construction supervision and other specialists involved in the planning and object supervision, with the preparation of a record of the result of the acceptance

- Compiling maintenance instructions for the facility

- Monitoring the tests of the functionality of the system components and the entire system

- Listing the limitation periods for warranty claims

- Cost determination and cost control

Commissioning is one of the most important tasks for the department specialists. Here, all specialists of SCHERZER ensure together with the respective sub-suppliers of the auxiliary systems to ensure a smooth initial start-up of the system. The basic parameters are checked and adjusted and the system is set up so that optimal results can be achieved.

After commissioning and setting all parameters, the system starts running. Here, the contractually agreed parameters of the system are checked and set out in a protocol.

Documentation and operating manual are one of the most important documents for the operation of the system for the customer and operator of the system. Here all documents are summarized in detail and handed over on a DVD or hard drive. Everything is arranged simply and clearly and all details can be easily found via links. The documents essentially consist of the following parts:

- Compilation of the graphical representation and computational results after completion, as-built documents

- Compilation of the system certificates, operating instructions, maintenance and repair instructions as well as official approvals for operation

- Manuals and releases of the entire project.

After-sales services, such as maintenance, spare parts and other services, are provided by the subsidiary Scherzer Umwelttechnik GmbH. This ensures continuous, secure operation of the systems.

You can find more information about after-sales service here!

Feel free to take a look at ours brochure to

range of services (coming soon)